Project Quick Facts

- Project: Charlestown Dredge Material Placement (DMP)

- Services: grading and excavation, stormwater management, underground utilities, roadwork and paving

- Location: Charlestown, Maryland 21914

- Timing: June 2024 to August 2024

- Project Manager: Rodger Burkins

Nestled along the serene shores of the Chesapeake Bay, Charlestown, Maryland, is a community that values its natural surroundings and waterways. With the ongoing efforts to preserve and enhance these resources, the Town of Charlestown embarked on a significant project to replace its dredge material placement (DMP) facility. This initiative, crucial for maintaining the town’s waterways, ensures that sediment dredged from the local harbor is managed effectively, preventing environmental degradation and supporting the local ecosystem.

The project, which began in June 2024, is a vital part of Charlestown’s long-term commitment to environmental stewardship. As the community looks to the future, the restoration of the DMP facility will play a pivotal role in preserving the town’s natural beauty and supporting its waterfront activities.

Replacing a Dredge Material Placement (DMP) Facility

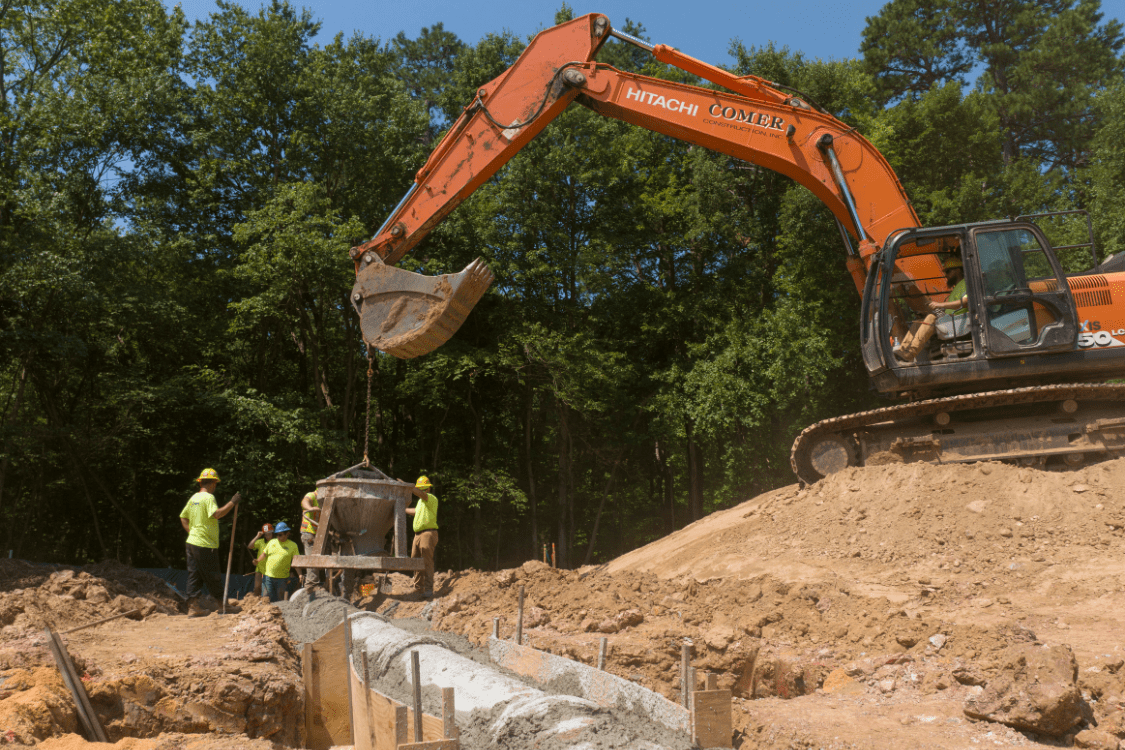

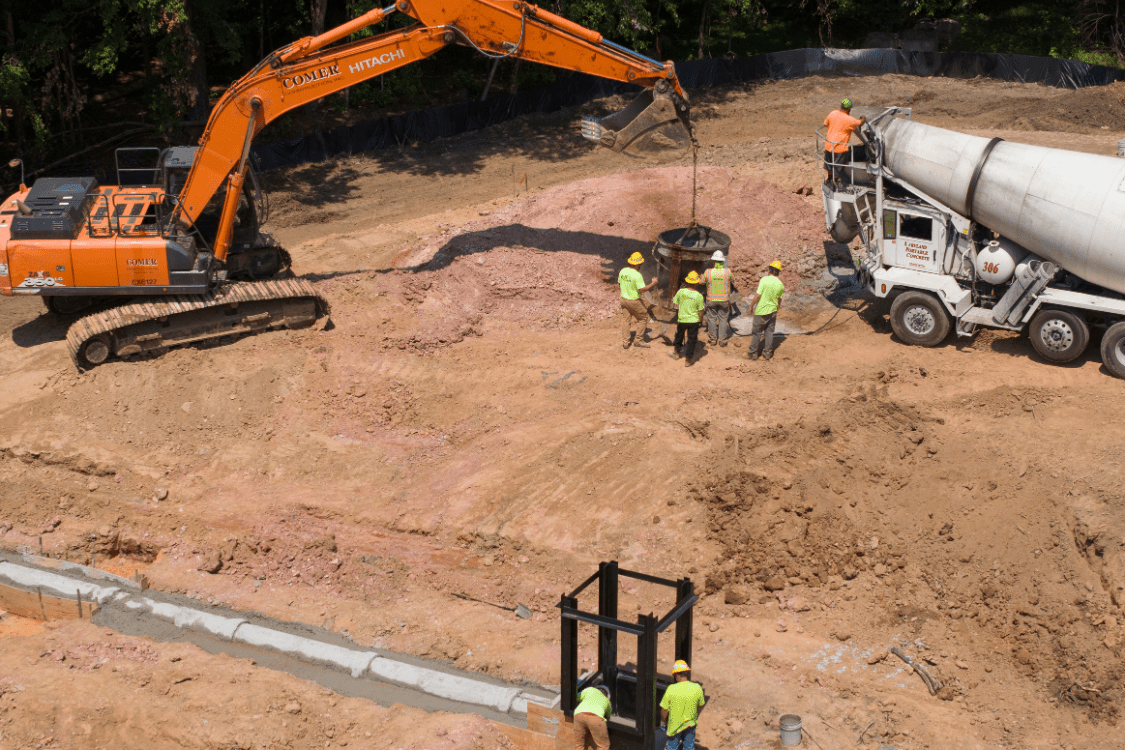

Comer Construction was proud to be selected for this important project. Our team, led by Project Manager Rodger Burkins, took on the challenge with a comprehensive approach, ensuring that every aspect of the job was handled with care and precision.

We started by setting up the necessary sediment and erosion control measures to protect the surrounding areas during construction. Clearing and grubbing the site was the next step, preparing the area for the main work. One of the key tasks was the removal and disposal of the existing weir box and 40 linear feet of old corrugated metal pipe (CMP). In their place, we installed a new weir box, 65 linear feet of reinforced concrete pipe (RCP), a sand filter diaphragm, and a headwall.

Building the dike embankment was another significant part of our work. We constructed a 600-foot embankment with an impervious core and a cutoff trench to ensure the structure’s durability. Additionally, we excavated and stockpiled nearly 7,800 cubic yards of material on-site. To improve access to the facility, we built a 295-foot road complete with a culvert. Finally, we landscaped and stabilized all disturbed areas, leaving the site not only functional but also looking better than before.

Grading and Excavation

Grading and excavation were central to the success of the Charlestown Dredge Material Placement project. Comer Construction’s expertise in this area ensured that the site was properly prepared for all subsequent phases of the project.

Key grading and excavation services provided for this project included:

- Clearing and grubbing: We removed vegetation and debris to prepare the site for construction.

- Excavation: Our team excavated and stockpiled nearly 7,800 cubic yards of material on-site.

- Dike embankment construction: We built a 600-foot dike embankment with an impervious core and cutoff trench to ensure durability.

- Site grading: We carefully graded the site to ensure proper drainage and stability for the new structures.

These measures helped to safeguard the project site and the surrounding area from potential environmental impacts.

Roadwork and Access Construction

As part of the project, Comer Construction was responsible for building a new access road to the DMP facility. This road was essential for ensuring easy and safe access to the site, both during and after construction. Our team applied their expertise in roadwork to create a durable and reliable roadway that would serve the facility for years to come.

Key roadwork services provided for this project included:

- Access road construction: We built a 295-foot road with a culvert, providing stable and durable access to the facility.

- Grading: The road was carefully graded to ensure proper drainage and longevity.

- Landscaping and stabilization: We completed the roadwork with landscaping and stabilization of the surrounding areas to prevent erosion and maintain the integrity of the roadway.

Underground Utility Installation

Underground utility installation was another crucial aspect of the Charlestown DMP project. Comer Construction was tasked with replacing outdated infrastructure and installing new, more reliable systems. This involved precise work to ensure that all new installations met the project’s strict specifications and would stand the test of time.

Key underground utility installation services provided included:

- Weir box removal and installation: We removed the old weir box and installed a new one, essential for the facility’s water management system.

- Pipe installation: Our team replaced 40 linear feet of 15-inch corrugated metal pipe with 65 linear feet of 15-inch reinforced concrete pipe, ensuring a more durable and long-lasting solution.

- Headwall installation: We installed a headwall to further support the facility’s water management infrastructure.

These services were integral to upgrading the facility’s infrastructure, ensuring it operates efficiently and effectively for years to come.

Your Partner for Comprehensive Site Construction in Maryland

Comer Construction offers a comprehensive range of services to meet all your site development needs. For the Charlestown DMP project, we brought our expertise to every phase, from site clearing and excavation to sediment control and utility installation. We ensured smooth access with road construction and enhanced the site’s appearance and stability through landscaping and stabilization.

Whether it’s site development, utility installation, or managing environmental projects, Comer Construction delivers top-quality results every time. Learn more about our Site Development Services, Utility Installation, and Road Construction services to see how we can support your next project.